Product Description

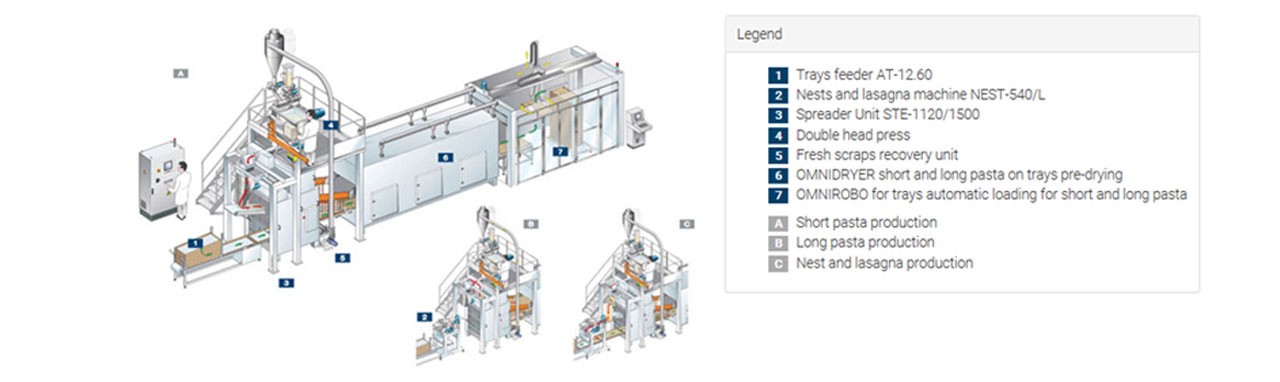

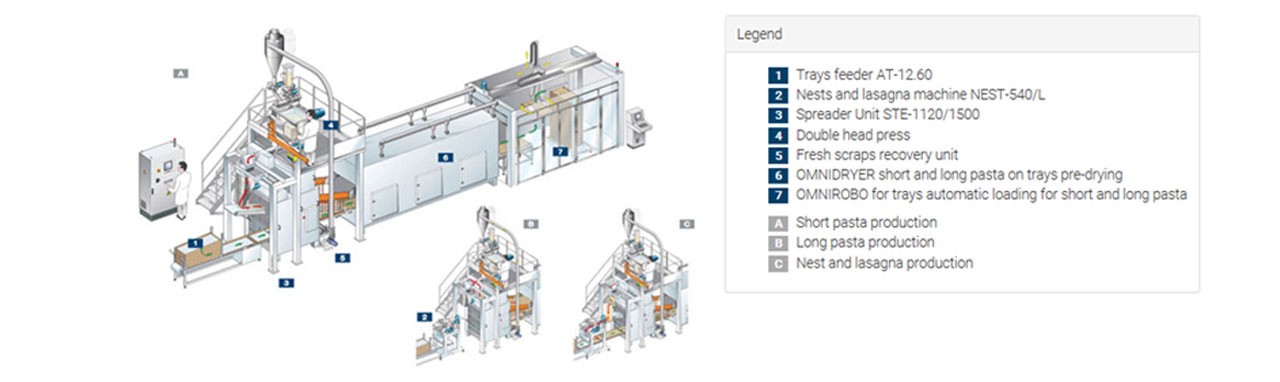

Storci Spa pasta production lines are currently used for spaghetti production as well as penne, paccheri, long tubular fusilli, conchiglioni, ziti, macaroni production and many other shapes. Pasta line can be completely automatic up to trolley filling, for both short- and long-cut pasta, while leaving to

traditional drying in the static chamber the task of completing shaping.

However, nothing is left to chance and a personal computer controls all drying phases in order to obtain a constant quality. All this leads to a reduced need of manpower and to a final product as tradition dictates. Best pasta processing.

Is it possible to make good dry pasta without durum wheat semolina? Sure! The consumer dedicates much more time in choosing these products than in choosing traditional pasta, so top quality is the indispensable key to success. Why producing this kind of pasta production lines? To guarantee growing market shares. Traditional systems produce dough mixes that are not very uniform and not of excellent quality. Additionally, they are complex and hence difficult to clean as well as being energy consuming. The difference? The Storci No-Glut pasta production lines are a concentration of experience and innovation with long-lasting guaranteed quality. Thanks to the new dough gelatinization system, it is possible to produce appetizing, high quality products for consumers requiring gluten-free pasta or for those who periodically like to choose alternative and healthy products. Advantages? Homogeneity in the pasta processing, high energy efficiency, control of the gelatinization level, easy cleaning. Choose the best pasta manufacturing, choose Storci